Deblistering Solutions

Sepha has developed a comprehensive range of automatic, semi-automatic and manual deblistering machines that offer speed, efficiency and safety in the recovery of valuable product from all types of rejected blister packs including push-through, child-resistant and peelable blisters.

Deblistering could help you reduce your cost. Blister packs can be rejected for several reasons including empty pockets, incorrect product, incorrect batch coding, leak test failure and inventory changes.

Packaging Solutions

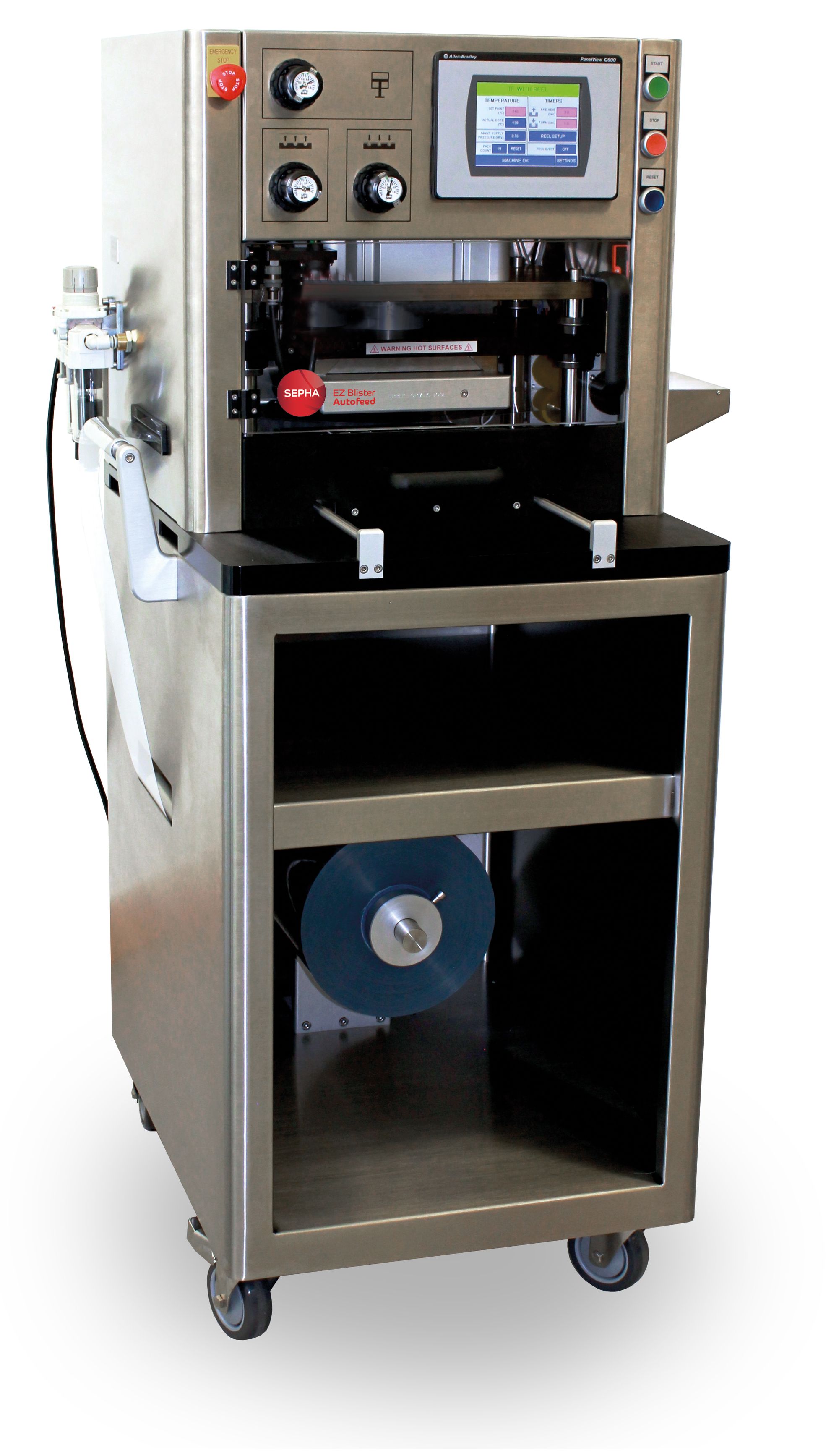

When small batches of blister packs or medical devices are required for clinical trials, stability studies, package development, specialist drugs or marketing samples, it can be hard to get these small batches fit in the busy schedule of your Production Department. Sepha’s range of small scale, high quality blister packaging machines and medical device packaging solutions give you the freedom to plan and budget your projects as and when required.

With the capability to handle all thermoform and cold-form materials the EZ packaging range offers high quality packs for all requirements including child resistant/peelable blister packs, sachets, ampoules, medical devices and monitored unit dose packs.

Leak Testing Solutions

Whether you are a pharma packaging or pharmaceutical manufacturer of blister packs, induction sealed bottles, sachets, pouches or medical devices, the quality of your packaging is key to ensure drug stability, as any defects can affect the shelf life and efficacy of the content. You need to be able to count on the accuracy of your leak detection procedures to minimize recalls and reduce the associated costs.

We offer a range of non-destructive, deterministic leak testing systems, specially designed to rapidly test for leaks in a wide variety of pharmaceutical packaging. Unlike the industry standard destructive test methods like Blue Dye Methylene, our testing methods are non-destructive, allowing product that has been tested to be returned to the production line.