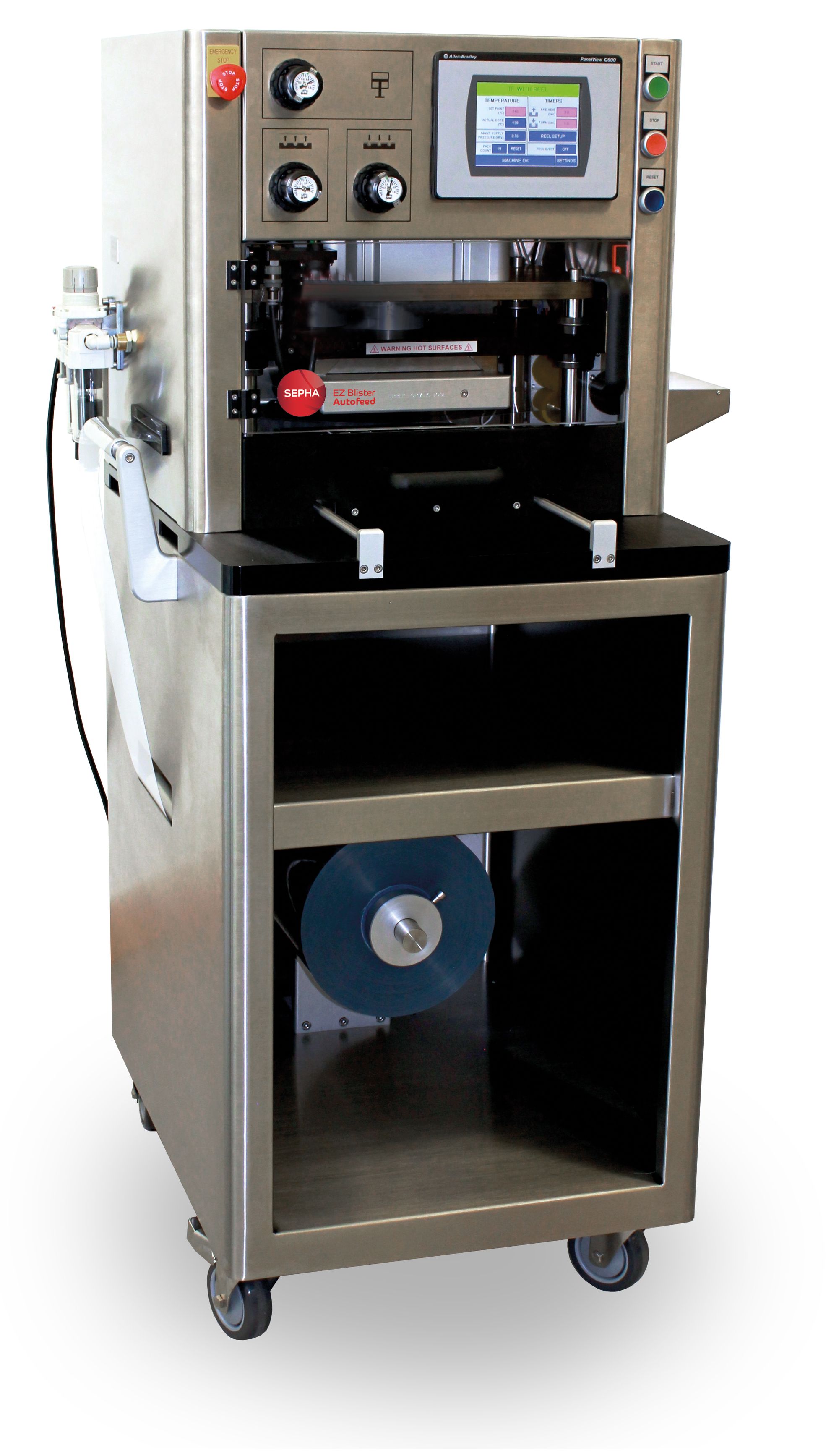

Its reel tensioning technology feeds material directly from the reel, increasing speed of forming and sealing operations.

· Customizable to individual commercial and manufacturing requirements

· Forming & Sealing Materials fed from reel holder using reel tensioning system to increase efficiency and reduce operator input

· Rollers hold material in place and feed predetermined length through system for forming or sealing

· Reel tensioning roller technology holds foil taut to ensure highest achievable level of foil tension when sealing

· Easy setup via HMI and minimal training required

· Tool-less changeover of format parts in less than 2 minutes

· Cold forming capability

· Perforated cutting tools (optional)

· All machine parts either grade 304 stainless steel, anodized aluminium or PTFE

· PTFE coated forming plates & knurled or heat sealing plates

· Operating speed of approx. 300 cycles per hour for forming and approx. 200 for sealing/cutting