ADVANTAGES

It is a fast and non-destructive system to evaluate the quality of film-coatings.

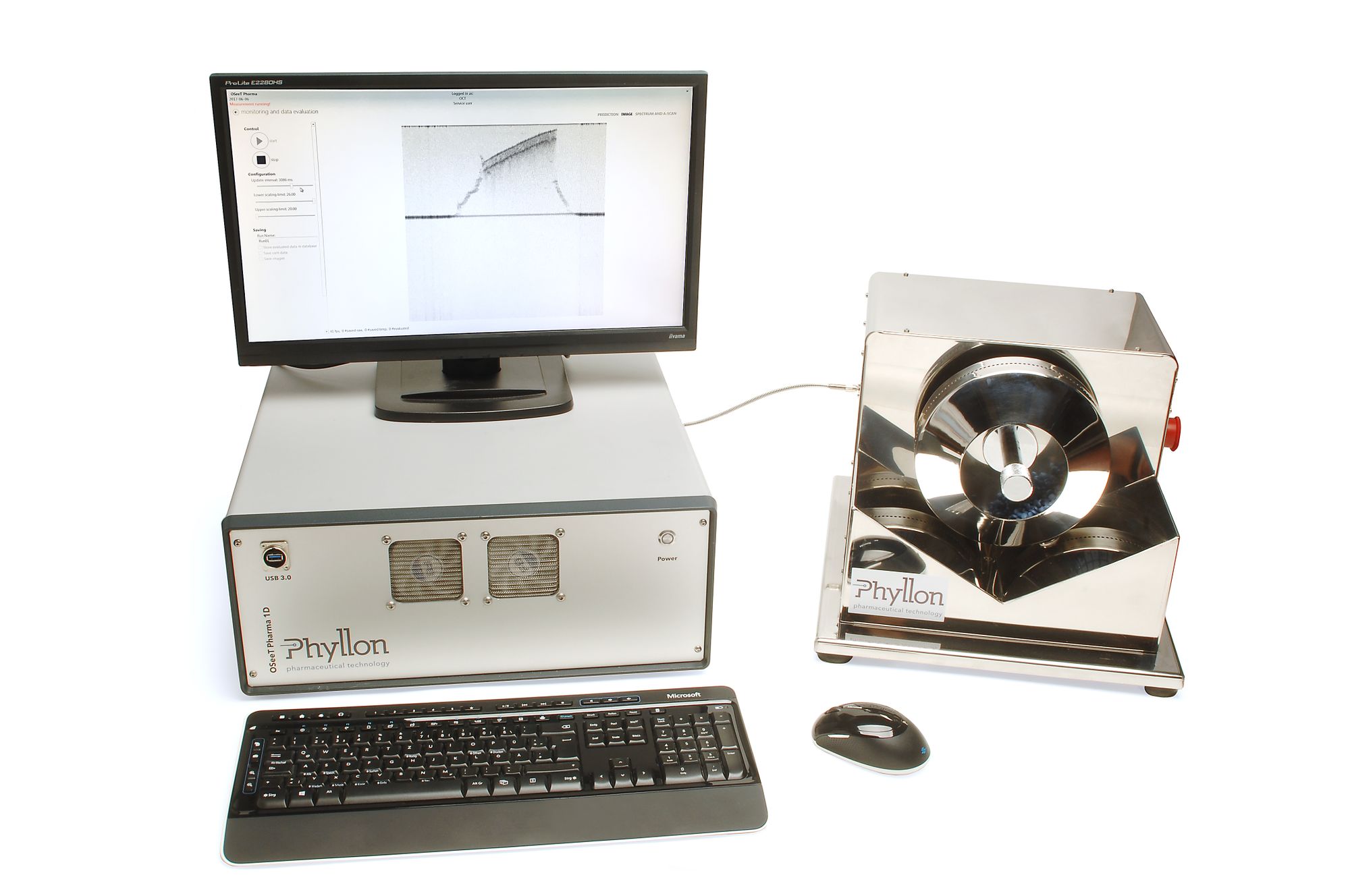

· The system is capable of scanning 60 images/sec. No other in-line and real-time technique can achieve the same. Once connected, the OSeeT provides immediate measurements of the thickness of the film coating, in microns. No specialized operator training is required.

An incredible level of detail.

· Through analyzing the pictures produced, it is possible to see the internal structure of the coating (i.e.: air bubbles and entrapped inclusions).

· Undesirable coating thickness variations can be revealed.

· The information that the OSeeT produces, for functional coatings above 10-15 microns, is an outstanding support for quality control of the product, both in development and also in production.

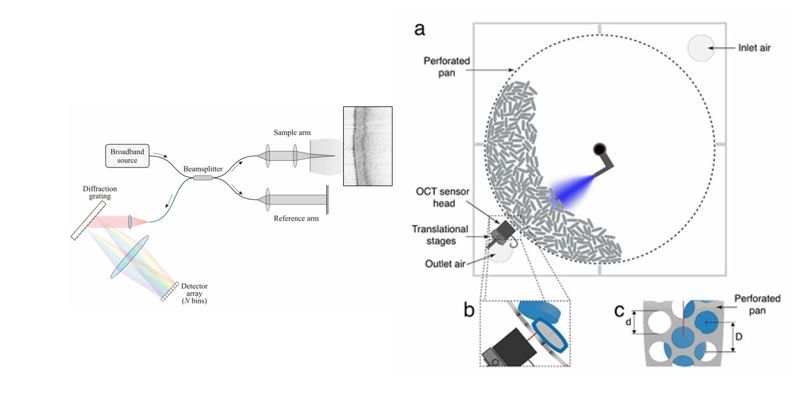

OSeeT provides direct measurement of the coating thickness.

· The measurement is based on a physical principle (light reflection and interference). It is not necessary to seek a secondary reference.

· It is also possible to review the roughness of the coating surface.

· OSeeT saves time during development and maintenance, greatly reducing TCO (“Total Cost of Ownership”).

· In order to calculate accurate measurements, only the refractive index of the coating solution needs to be known.

Through using OSeeT it is possible to closely monitor the performance of pan coaters.

· The measurements and the images can immediately reveal malfunctioning or poor set-up of the coater and also if the coating solution or suspension has been prepared properly.

The 1D OSeeT probe is small.

· This facilitates positioning inside the pan in existing coaters. The probe is not in direct contact with the product when used with perforated pans.