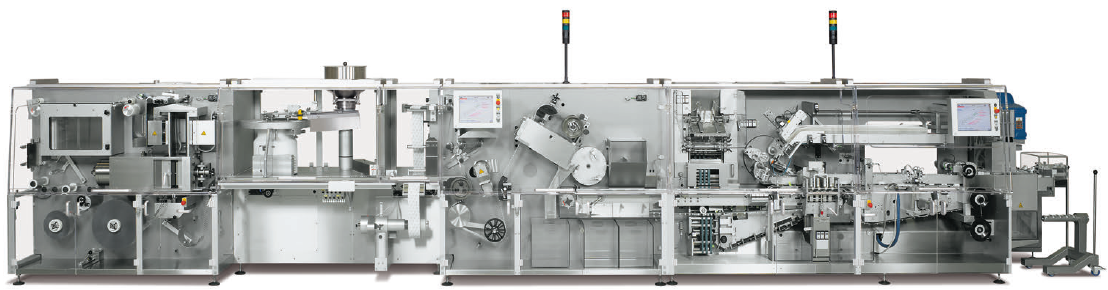

The modular construction is reflected in the clear division and delimitation of zones. All functional areas are easy to access and quick to clean. Servo-motor driven feeds allows precise positioning of blisters before sealing, cutting and perforating, regardless of the foil’s shrinkage behavior. Centralized format data management via the control terminal provides support for a quick format change. You can do it in less than 45 minutes

With the CP400, Mediseal offers a high-output singletrack blister machine. More than 20 years of continuous improvement have made this machine a fully-fledged product which with its exemplary GMP design guarantees maximum production reliability and an output of up to 400 blisters per minute. It can easily upgrade the CP400 to a compact line, using our direct blister transfer to a Mediseal cartoner

CP400 configuration options:

- Base foil storage for roll changes without having to stop the machine

- Switchable pre-stretching unit for forming aluminium, PP and Aclar foils

- Dosing systems for every type of tablet

- Inline lidding foil printing

- Fully integrated fill check

- Roller or platen sealing station

- Manual insertion chute for returning ejected good blisters to the packaging process

- Infeed systems for pack inserts

Special features of the CP400 at a glance:

- High-performance one-lane operation

- Maximum flexibility thanks to fast format changes

- Low maintenance and servicing costs

- Direct product transfer to the cartoner, with no fault-prone intermediate stacking units.

- A minimum of format parts

- A wide range of configuration options