Stickpack packaging is becoming increasingly popular among consumers. The portioned product and its quick, uncomplicated consumption, even on the go, provide consumers with significant convenience.

The modern shape of the pack means that for the same fill quantity, stickpacks consume up to 40% less material than sachets. This means a reduction in material costs, as well as an improvement in the CO2 footprint of each product.

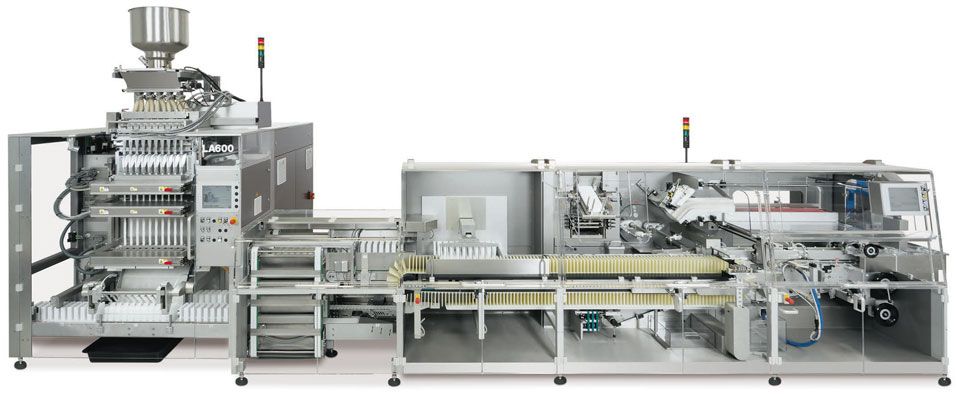

The LA600 stickpack machine was developed specifically for the needs of the pharmaceutical market. Linking together the LA600 SP and the P1600 cartoner, which has already notched up high sales, creates an ideal combination of proven technologies.

The sticks, positioned using the side-load method, are packaged at

very high speed. This is possible thanks to the excellent design of the stick guidance system along the process chain. Free fall or random distribution of the stickpacks is reliably prevented. This high process reliability, coupled with excellent output quality, guarantees high overall equipment efficiency (OEE) for our customers. (If necessary, it can also work in a stand-alone configuration).

Excellence and efficiency.

The ideal accessibility of the line provides the operator with an optimal view of the packaging process. Short downtimes for maintenance and the sensational cassette wet-cleaning facility also ensure outstanding equipment efficiency.

Technical details

- Stick width 15-40 mm

- Stick length 45-160 mm

- Output up to 1000 stickpacks/min.

- Stickpacks per carton 5-50

- Output up to 100 cartons/min.

Flexibility

- Liquids, free-flowing granules, powders and pellets.

- Large format range for stickpacks, including multiple formats of

different widths. - Large format range for cartons.

- Any number of stickpacks per carton.

- Glued or tuck-in closure.

- Leaflet or other pack inserts such as booklets.

Equipment efficiency

- Direct stickpack guides ensure a stable production process

- Fast access to the machine for cleaning and maintenance

- Buffer between LA600 SP and cartoner compensates for microinterruptions

Future-proof

- A modular design which enables the line to be optimally adapted to

future requirements. - Possibility of adding extra functions such as leak testing or a balance at any time.

- Consistent modular design:

To achieve the absolute maximum in terms of performance,

two stickpack machines can be linked to one cartoning machine. - The line also offers scope for future implementation of additional customerspecific

functions. For example, leak testing or a weighing unit can easily be

retrofitted.